M6 Test Handler

Flexible product test handling from high-mix to high volume production

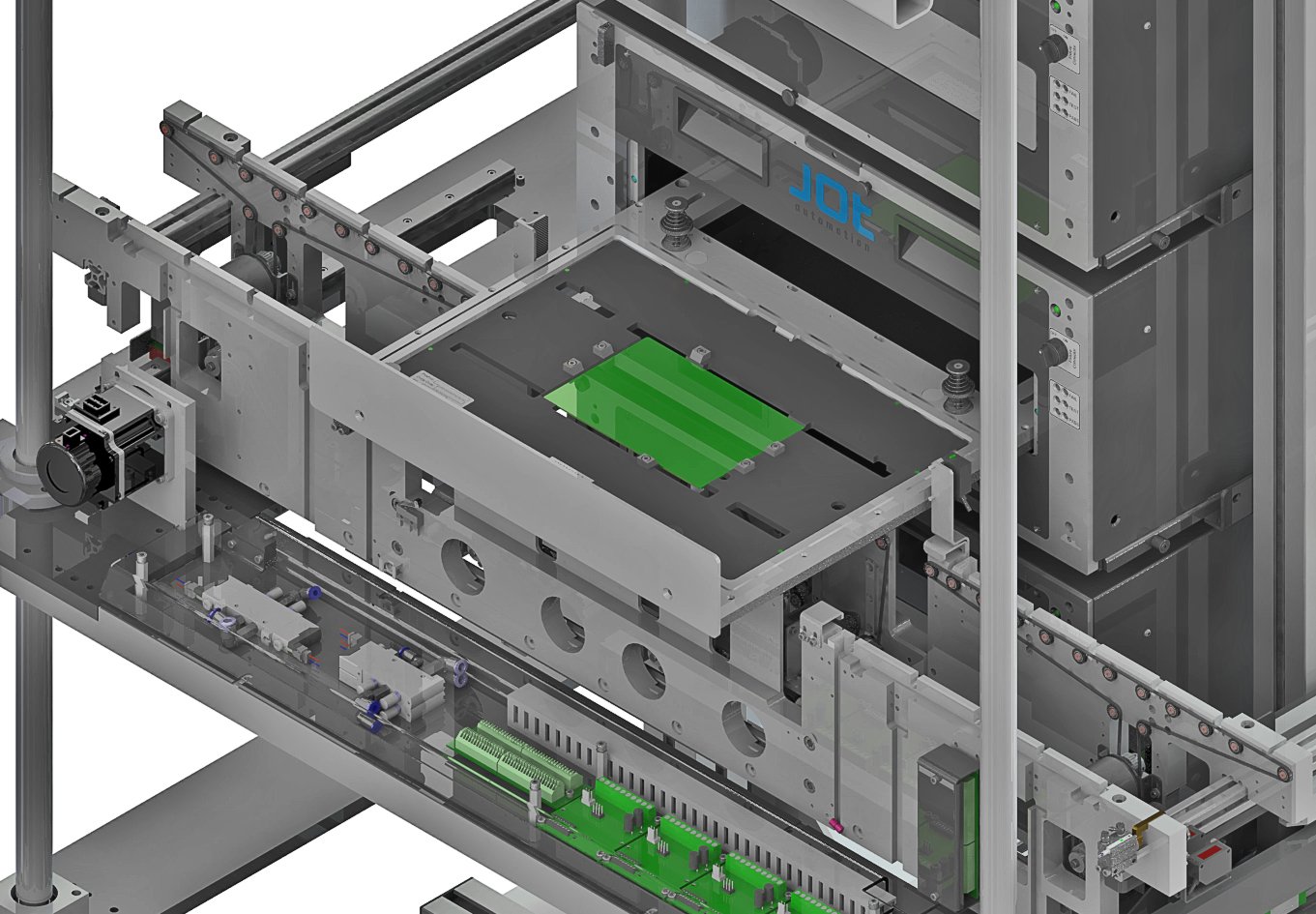

At JOT, we’re always working on new ways to make test handling faster and easier. That’s why we created the M6 Test Handler. The M6 is perfect for high-mix and high-volume testing and also hits the sweet spot for any line that requires flexible PCB testing capabilities – especially when device size and speed matter.

Best of all, because it’s part of the modular M Test System, the M6 is truly scalable. The M6 utilizes the same M Test Boxes as the other M Test Handlers – making it yet another smart, flexible, and cost-effective choice for your ever-changing, and growing, testing needs.

The M6’s best advantage is achieved when a test application is created by embedding measurement devices inside the M box, e.g. a flash application. The test system is then fully independent and exchangeable between automated handling systems and manual workstations.

Case study: See how Siemens automated their test line using the M Test Handler

Learn more about how Siemens utilized the M Test Handler to automate the testing of their SIRIUS industrial control products.

THE JOT M6 TEST HANDLER MAKES PRODUCTION EASIER

THE SHAPE OF THINGS TO COME

Ideal for high-mix and high-volume testing purposes.

EASY, ERGONOMIC ACCESS

Faster product handling for easier line modifications.

SMARTER BY DESIGN

Industry 4.0 technology for autonomous device interconnectivity.

Maximal testing capacity. Minimal footprint design. Major production line win.

Best of all, because it’s part of the modular M Test System, the M6 is truly scalable. The M6 utilizes the same M Test Boxes as its predecessor the M5 Test Handler, and the all-new M12 Test Handler – making it yet another smart, flexible, and cost-effective solution for your ever-changing, and growing, testing needs.

The M6 is the optimal solution for manufacturers who want to automate their PCB and pallet-based testing. With up to 6 test boxes and 2 test phases, you are easily able to set up your testing environment for high-mix and/or high-volume configurations.

M6 Test Handler Highlights

- A simple, cost-effective way to automate PCB and pallet-based testing

- Safe, reliable product handling

- Quick-adjust ease: no product-specific parts

- Faster handling of smart products

- Industry 4.0 autonomous interconnectivity

- Truly scalable for growing test needs

- Reusable, application-specific test boxes

- M Test Boxes compatible with other M Test Handlers

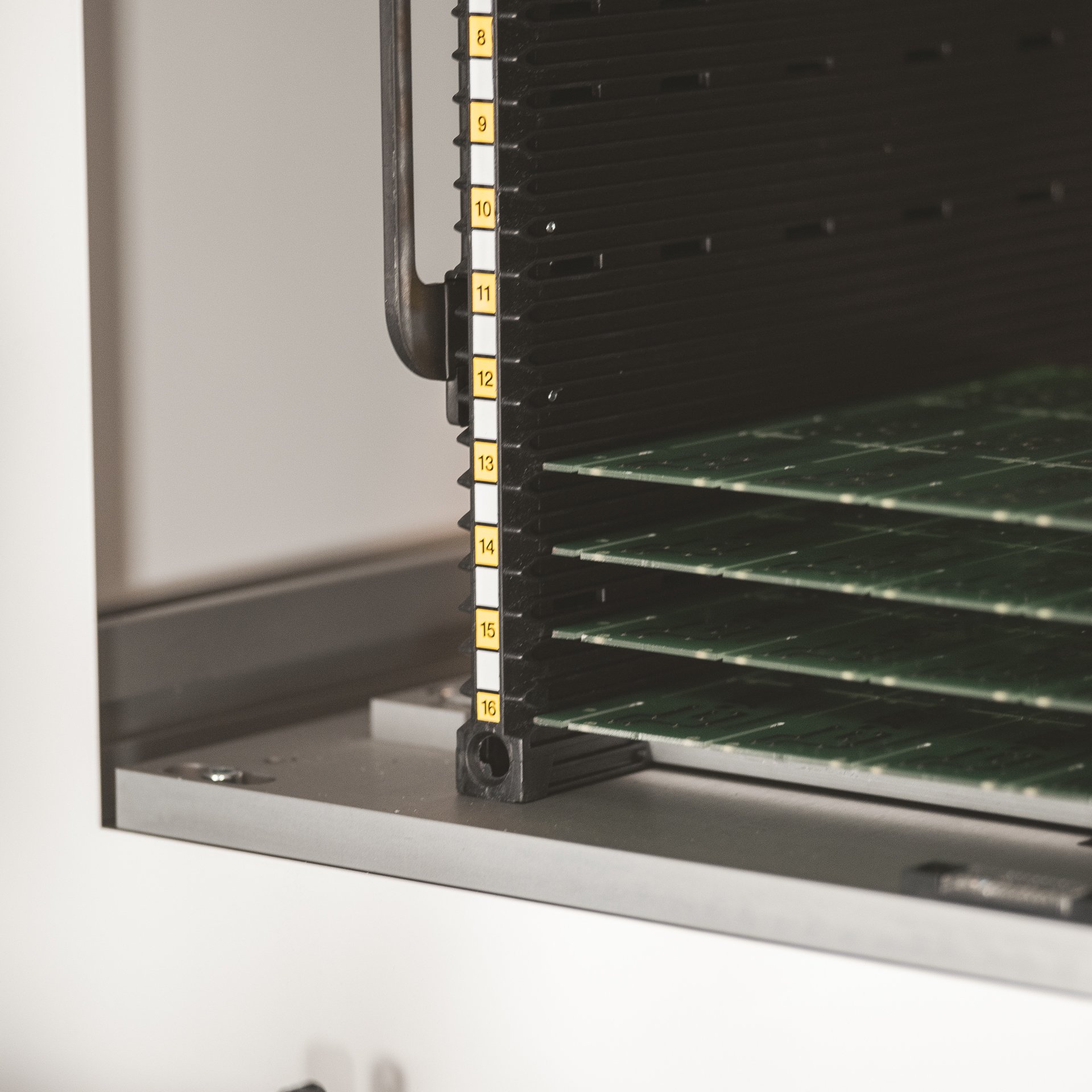

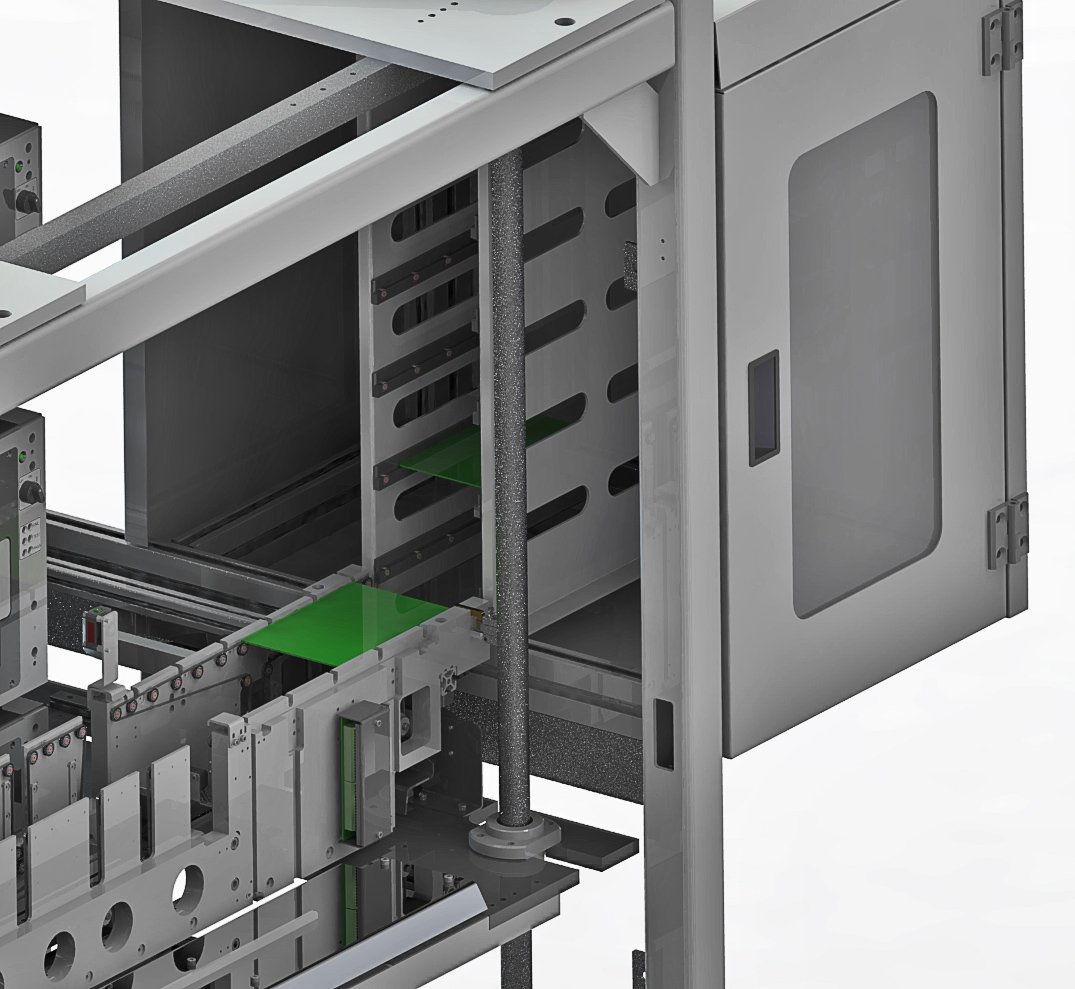

- Test Boxes are fully independent, just remove them from the M6 rack and use them in off-line testing

KEY PRODUCT FEATURES:

- M Test Boxes compatible with other M Test Handlers

- Boxes are fully independent, simply remove them from the M6 rack and use them in off-line testing

- Fail product separation to an integrated magazine

- Spacious service-friendly construction

- Ergonomic workspace

- Touchscreen UI with base statistics and service capability

- Easy start-stop operability

STANDARD FEATURES:

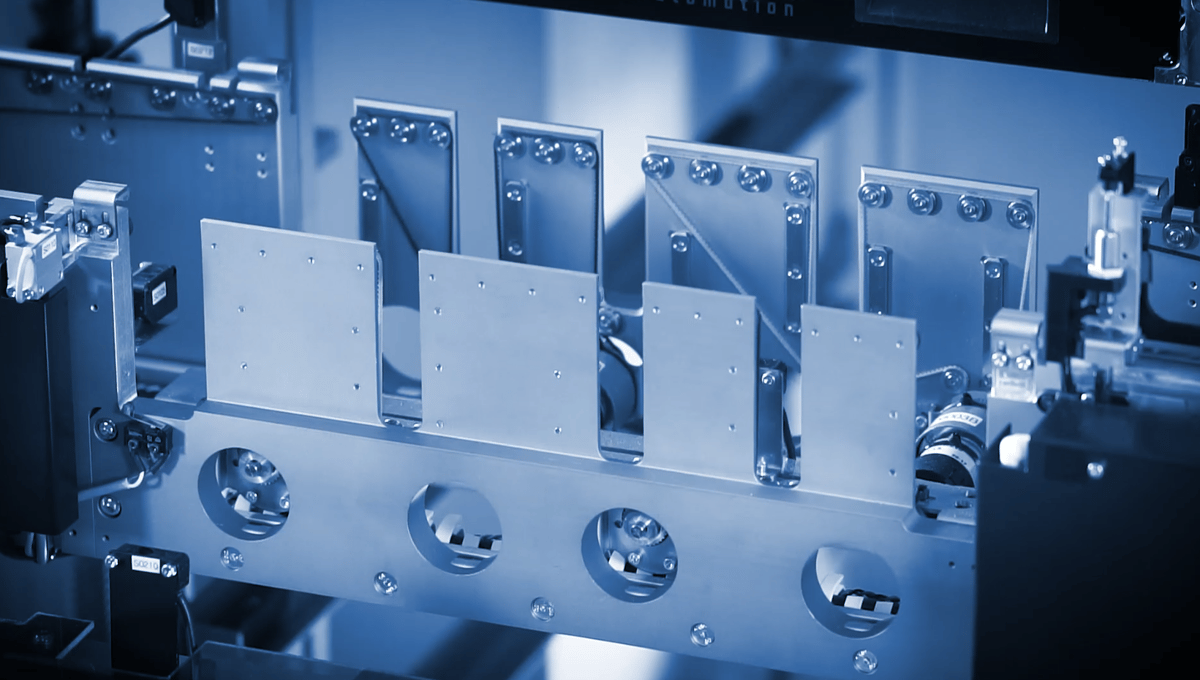

- Max test box amount 6 pcs

- Max 2 test phases in one handler

- Automatic width adjustment

- Pass-through mode

- Max 50 saved product configurations

- IPC SMEMA 9851

- Basic statistics on UI

- Three user levels

- Serviceability supporting UI

- Automatic fixture detection

OPTIONAL FEATURES:

- Fail buffer

» Integrated at the handler outfeed side

» 2 magazines included

» 3 alternative magazines - DUT identification

» Readiness for code reader integration

DOWNLOAD PRODUCT DATASHEET

M - STANDS FOR MODULARITY

The core idea of the innovative M Test System is to provide a testing solution that is easily adaptable to a variety of production requirements. Product handling is an important part of the M Test System and it’s specifically designed for system scalability. And because all application-specific features are housed inside each easily tailored M Test Box, the nature of the test process may be adapted dramatically – simply by changing the box.