Battery assembly solution

FULLY CUSTOMIZABLE TURNKEY SOLUTION FOR BATTERY ASSEMBLY

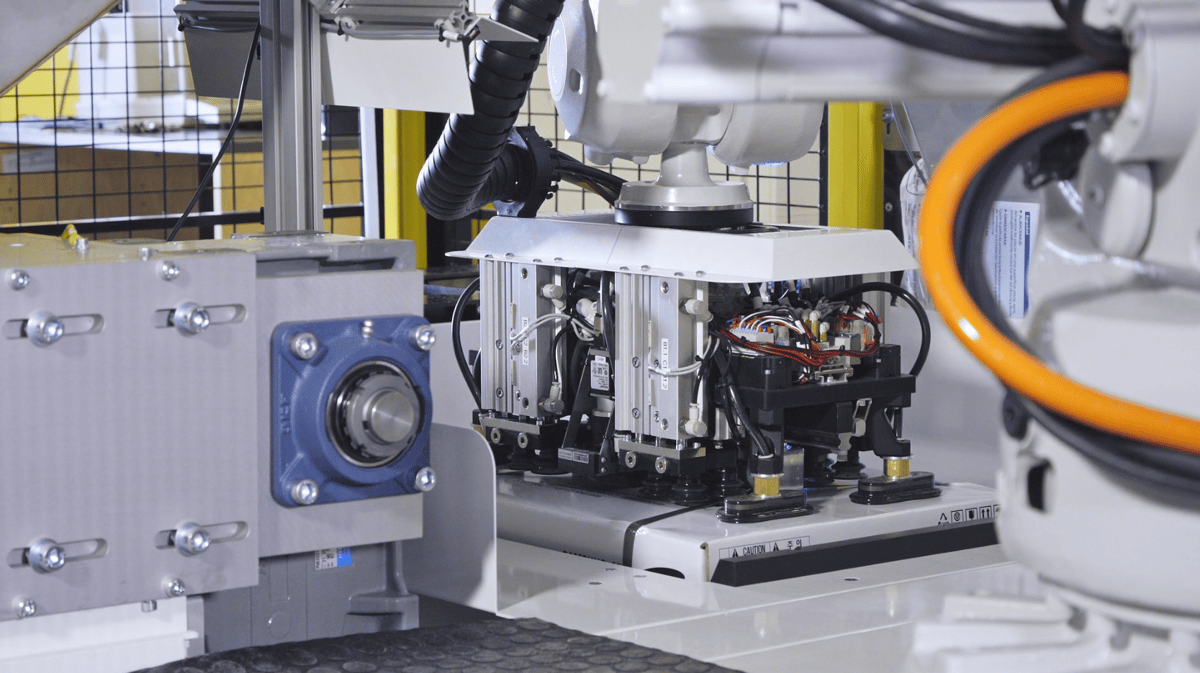

Watch the JOT Battery Assembly Solution in action.

JOT BRINGS SPEED, PRECISION AND SCALABILITY TO EVERY BATTERY ASSEMBLY LINE

JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing. The Battery Assembly solution is built precisely to each customer’s requirements and preferences. And thanks to its unique modular design – the hallmark of all JOT products – your options for control are virtually limitless.

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

Case study: See how we helped a leading energy solutions manufacturer automate their production

HIGH-GRADE ASSEMBLY SOLUTION FOR BATTERY AND ENERGY STORAGE SYSTEMS

Custom built for your assembly line

All-in-one solution tailored per your every requirement and specification.

The sky’s the limit

Built-in electrical testing plus expandability for welding, final product testing and more.

Good to grow

Full-scale production solution with buffering and automatic fail sorting.

COMPREHENSIVE, FULLY CUSTOMIZABLE TURNKEY SOLUTION FOR BATTERY ASSEMBLY

The JOT battery assembly solution is made for high-grade battery assembly for electric vehicle, energy storage and other battery manufacturers. Tailor-made, in fact, per your exact requirements. The beauty of every JOT solution is that your assembly line needs to come first. We know you need speed and accuracy across your entire production line.

Whether it’s material handling, assembly capabilities or final-product testing, we’ve got you covered. Need to ramp up production quickly? We’ve got your back there too with JOT’s trademark modular design that provides unrivaled scalability.

Key features:

-

Comprehensive solution for automated battery assembly

-

Modular design with options for material handling and testing, including assembly, welding and final-product testing

-

Built-in electrical testing

-

Buffering capability

-

Automatic fail sorting

-

Laser welding

-

High-grade safety features

-

Custom-built according to your specifications

Download Battery assembly solution flyer

Learn what makes the JOT battery assembly solution a reliable and cost-effective solution for your production line. Click to download our datasheet for more detailed product specifications.

DESIGNED FOR PRECISION. AND FOR GROWTH

JOT built its reputation on speed, precision and scalability. When the world’s leading manufacturers need a solution, they turn to JOT. Not only for assembly and testing, but also for its industry-leading modular-design thinking. Not to mention the way JOT always has your bottom line in mind. With a JOT customisable solution, you get every assembly and testing capability you may need, without having to pay for features you don’t.

Revolutionize Your Battery Assembly Process with Automation

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production. Our advanced automated battery assembly systems are designed to meet the demands of modern manufacturing, enabling scalability, reliability, and precision without sacrificing floorspace.

Our battery assembly line solutions cater to diverse battery formats and configurations, offering unmatched flexibility and efficiency. From small-scale production to high-volume manufacturing, our systems provide the tools needed to streamline processes and reduce errors. With battery assembly automation, you can enhance consistency, minimize waste, and maintain strict quality control, all while reducing operational costs.

Whether you’re producing battery modules or packs, our solutions support various applications across industries, including electric vehicles, power electronics, and energy storage systems. Our automated battery assembly systems are equipped with advanced technologies such as precision handling, automated testing, and real-time monitoring to ensure every battery module meets rigorous standards. By automating critical steps in the battery module assembly and battery pack assembly processes, we help manufacturers achieve unparalleled efficiency and output.

JOT Automation’s expertise in battery assembly automation allows us to deliver customized solutions tailored to your production needs. Our systems can handle the complexities of modern battery assembly lines, ensuring smooth operation, adaptability, and minimal downtime. By combining state-of-the-art technology with industry insights, we empower manufacturers to stay ahead in an evolving market.

Take your battery assembly operations to the next level with JOT Automation. Whether it’s battery module assembly, battery pack assembly, or fully automated, end-of-line battery assembly, our solutions are designed to drive innovation, improve productivity, and ensure long-term success. Contact us today to learn how our battery assembly automation solutions can transform your production line and deliver the performance you need in today’s fast-paced market.