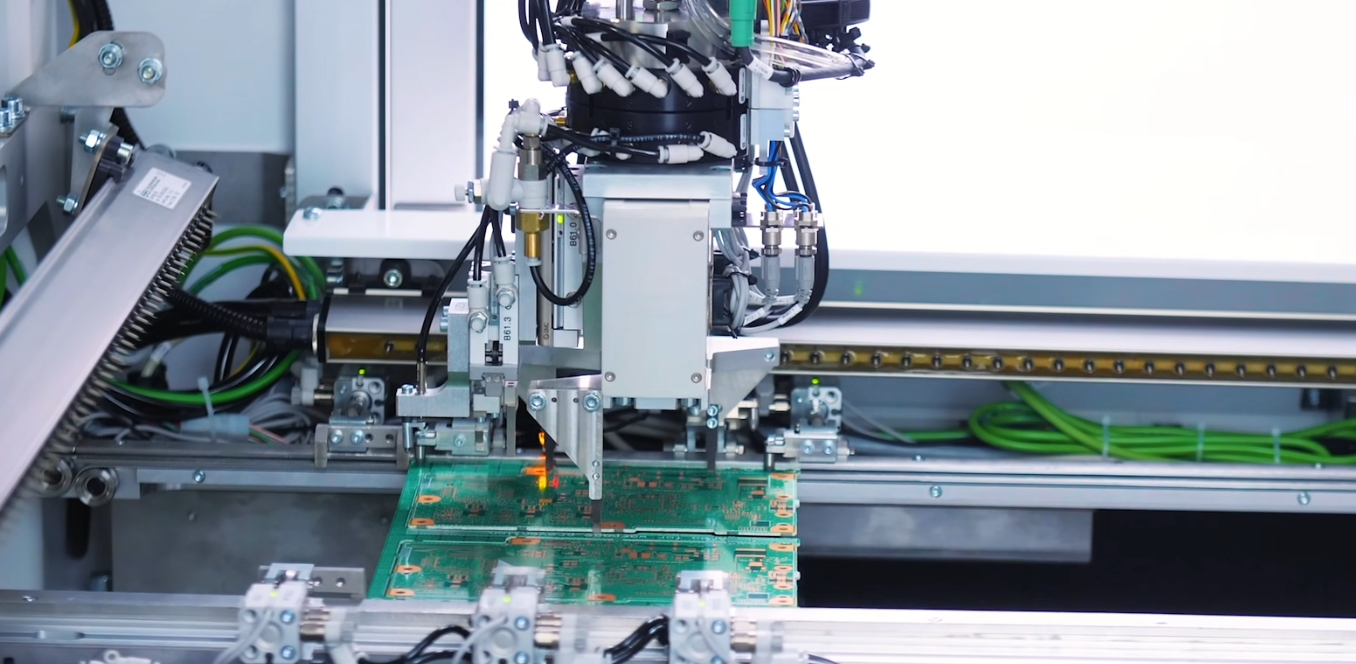

Router 620

Fast. Scalable. Fully automated.

JOT Automation Router 620 provides you with accurate and clean PCB module cutting from panels. It is fast, compact and can handle wider boards than our previous routers. Easy and precise cell teaching ensures production keeps running constantly.

JOT Automation Router 620 is quick to set up and supports multiple languages off the shelf. Automatic dust removal system keeps modules dust-free and requires less machine maintenance.

KEY PRODUCT FEATURES:

- Automatic tool change system

- Accurate and clean cut

- Easy and precise cell teaching

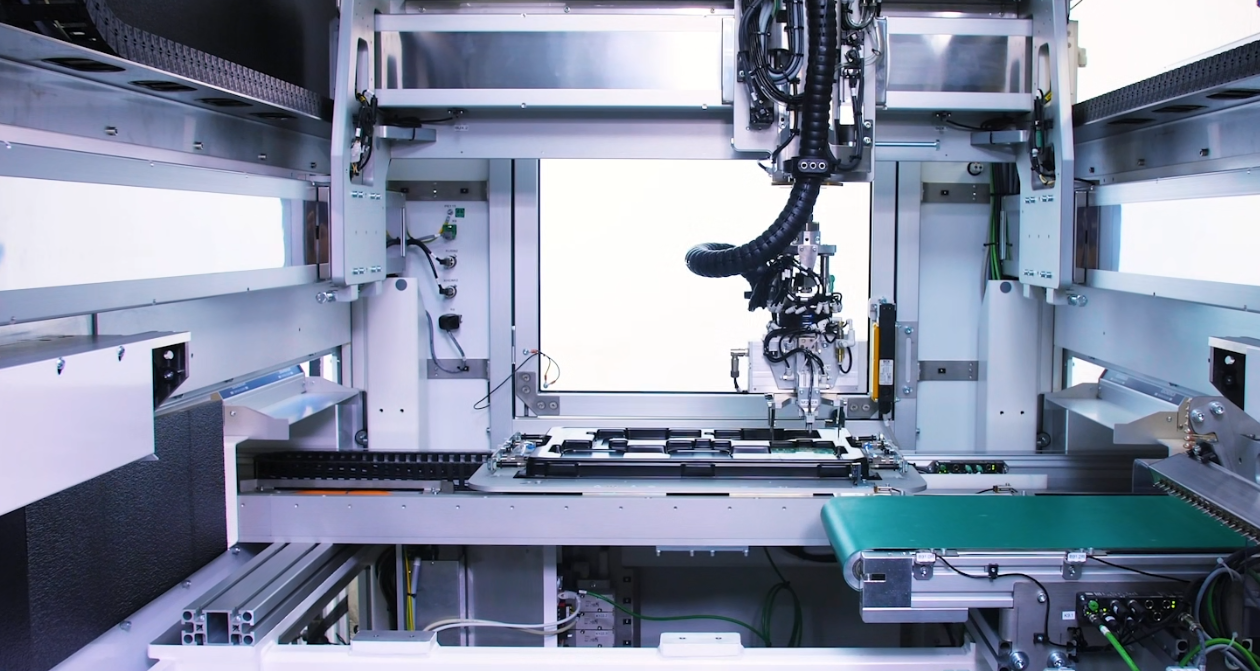

- Compact footprint

- High production volumes

- Short product setup time

- Built-in multi-language support

- Dust removal system

STANDARD FEATURES:

- Infeed conveyor flow from left to right

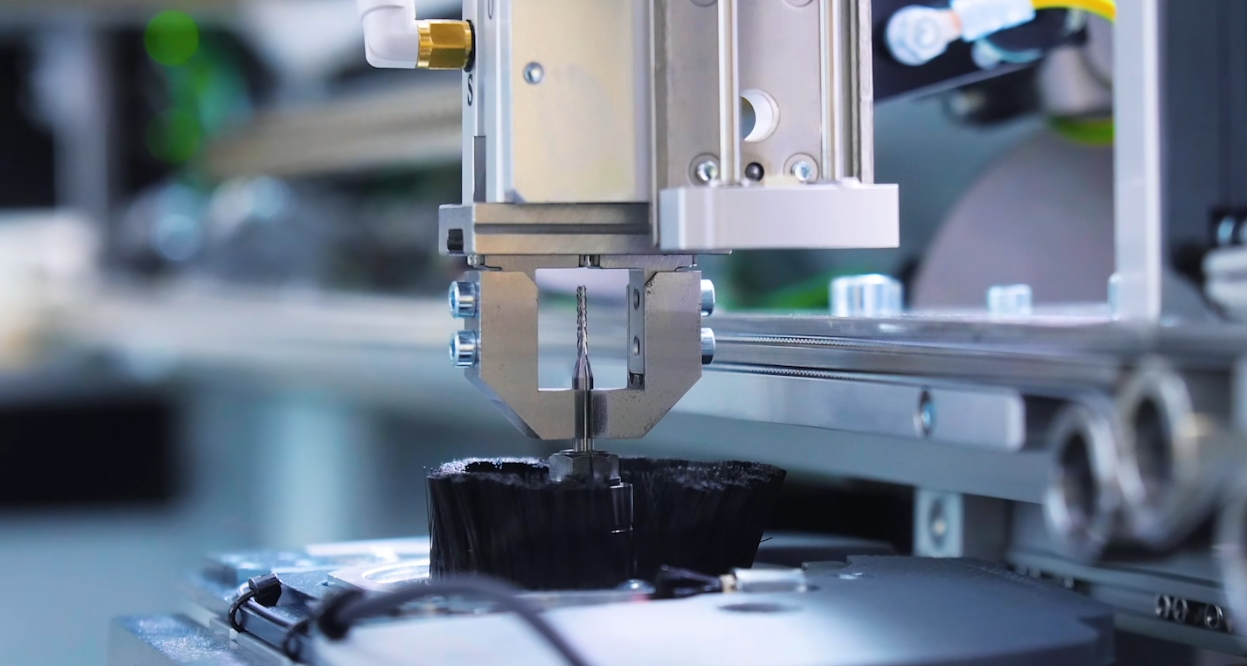

- Cutting tool breakage control

- Pneumatic milling tool change

- HF motor spindle and converter

- PC based machine control software

- DXF file support for teaching cutting points

- Automatic tool change: 10 spare spindles

- Vacuum monitoring system

- Laser sensor system for teaching cutting points

- Crash detection sensor

- Ionization

- Graphical UI

- Touch screen

- ESD safe design

- CE safety compliant

OPTIONAL FEATURES:

- Transport direction from right to left

- Pallet output conveyor

- Flatbelt output conveyor

- Tray feeder output conveyor

- Fail module handling: verification and rejection from cell, rejection conveyor

- Code reader

- Additional cleaning system after depaneling

- Servo gripper

- Pneumatic gripper

- Gripper finger change unit

- Tool rack for product specific fingers

- PCB flipping unit after depaneling

- Dust removal system

DOWNLOAD PRODUCT DATASHEET

Learn more about the JOT Router 620 that makes depaneling PCBs easy and flexible. Click to download the datasheet for more detailed product specifications.