Router 400

Fast. Scalable. Fully automated.

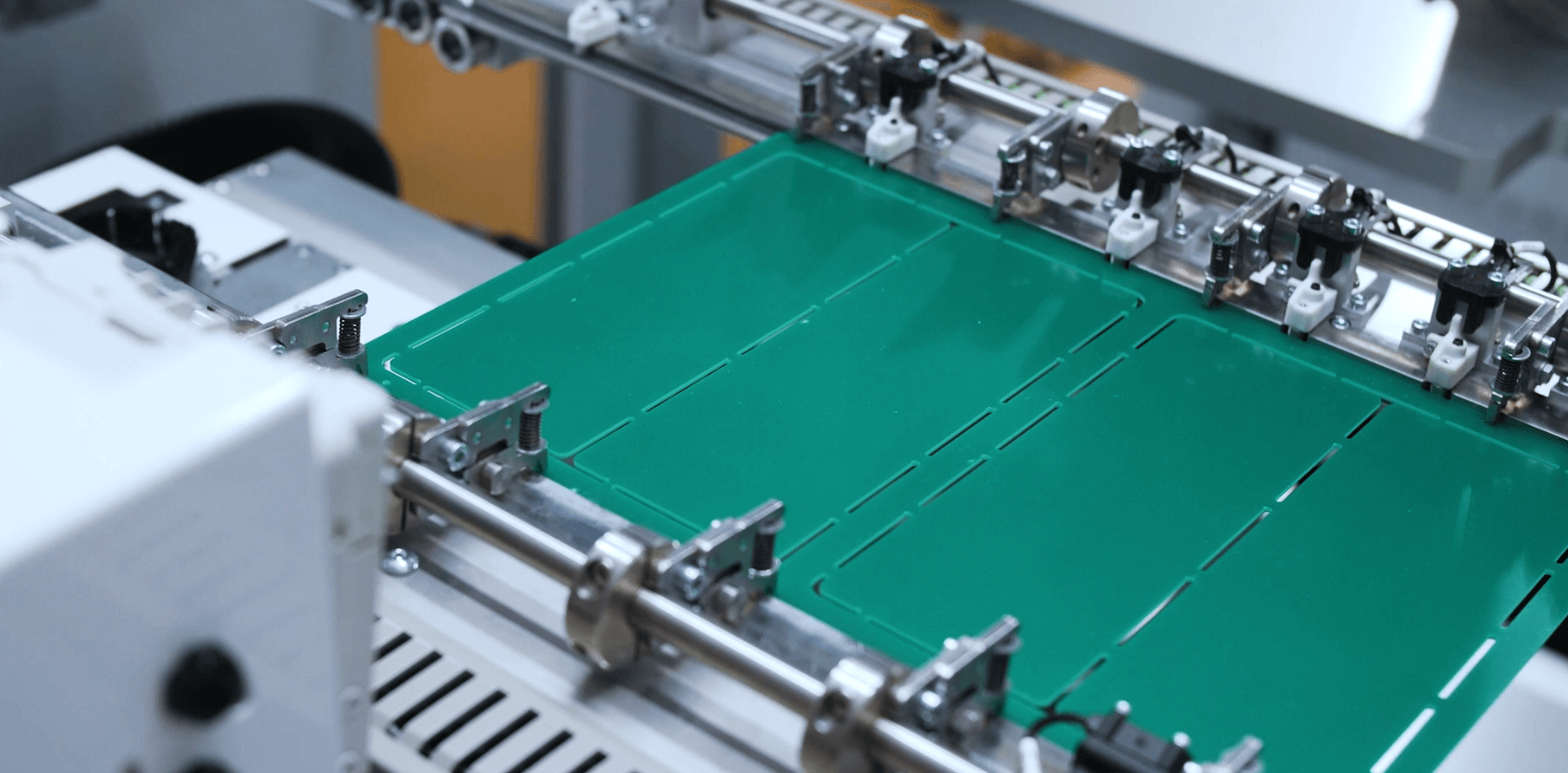

JOT Automation Router 400 provides accurate and clean module cutting from panels. It is fast, compact, and can handle up to 400mm wide boards.

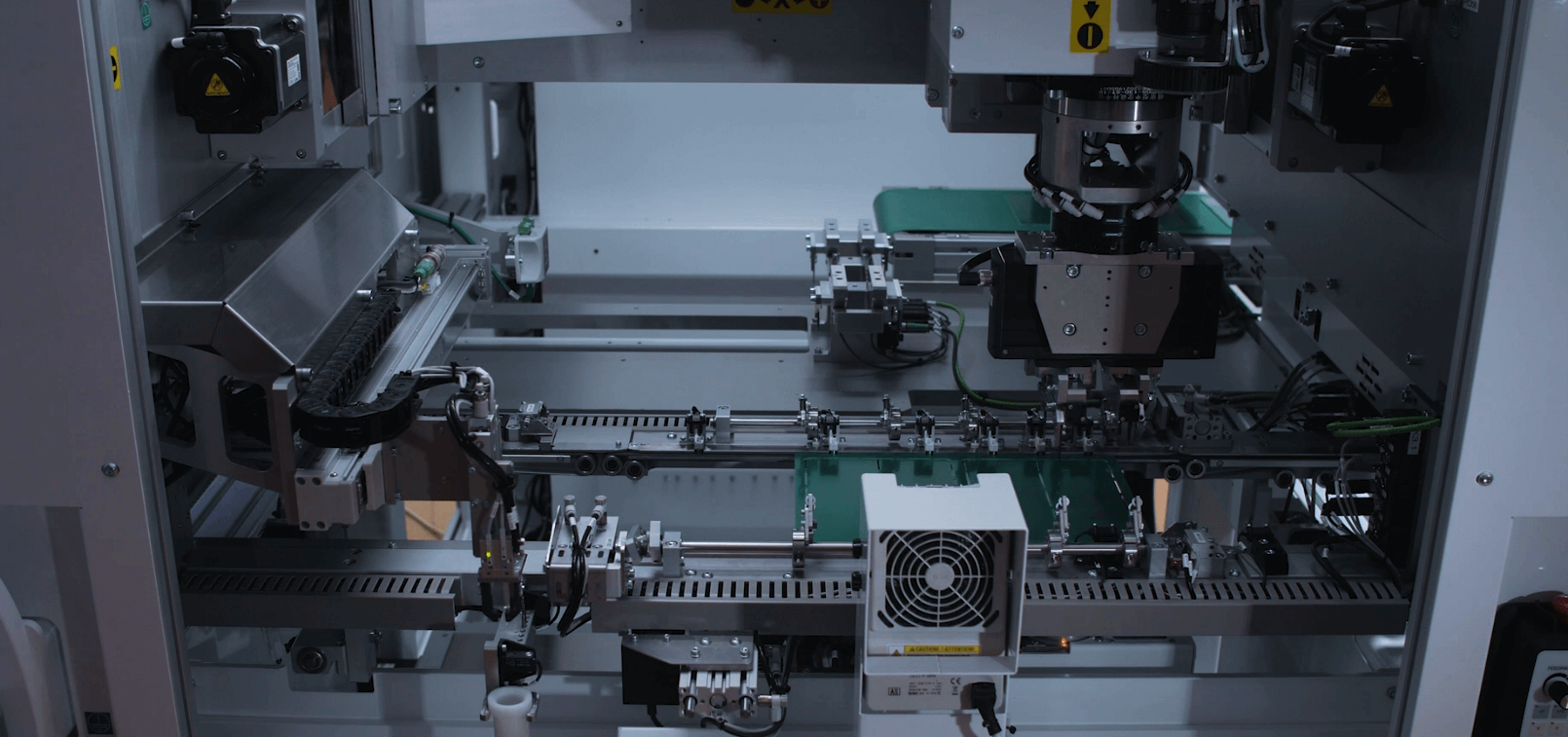

JOT Automation Router 400 configurations enable you to find a suitable solution starting with simple "Depaneling and placement to flat belt outfeed" up to sophisticated camera aided process control with automatic gripper and tray handling.

With a multitude of options, the Router 400 is our most comprehensive solution for automated depaneling / routing of PCBs.

KEY PRODUCT FEATURES:

- Separates PCB panels from the panel

- Accurate and clean cut

- Easy and precise cell teaching

- Compact footprint

- High production volumes

- Short product setup time

- Built-in multi-language support

- Dust removal system

STANDARD FEATURES:

- HF motor spindle with air cooling

- Cutting tool breakage check

- Manual milling tool change

- Brush in the spindle at a fixed height

- Vacuum level monitoring for dust extraction

- Dust extraction outlet pipe (Ø51mm) on right side of the machine

- Waste part outfeed flat belt conveyor, flow direction same as input conveyor

- ESD safe bin for waste parts (L800*W600*H220mm)

- Ionization

- ESD-safe design

- 4 light beacon in front side and in rear side

- PC-based machine control software

- JOT graphical user interface

- DXF file support for teaching cutting points

- 24“ Touch screen, Keyboard, Mouse

- IPC SMEMA 9851 electrical interface

- CE-safety compliant

OPTIONAL FEATURES:

- Input conveyor

- 1 segment or 2 segments

- Flow direction from left to right or from right to left

- Manual or automatic width adjustment

- Tool diameter inspection (top camera option required)

- Automatic tool change with magazine for 10 spare cutters

- 2D Code scanner(s) for PCB panel

- Fiducial or PCB edge check with top camera

- Fiducial or PCB edge check with bottom camera

- Force sensor on upper gantry for crash detection

- Gripper quick change adapter with pneumatic and electrical connections

- Pneumatic gripper

- Servo gripper

- Automatic gripper finger change with rack for product specific fingers

- Movement of spindle brush enables PCB cutting nearby the component on bottom side

- Spindle brush movement by pneumatic actuator

- Spindle brush step movement by servo actuator

- Dust extraction outlet pipe (Ø51mm) on left side of the machine

- Extra outlet pipe (Ø51mm) on right side of the machine for connecting a hose for manual cleaning

- Extra cover for waste bin and waste part outfeed

- PCB straightening with pneumatic support from bottom side

- Teach pendant

- PCB flip unit after depaneling

- Cutting quality check by camera (details to be defined)

- Taifun cleaning system after depaneling: PCB top side/PCB bottom side (details to be defined)

- Remote monitoring camera

- Extra 24“ touch screen in rear side of the machine

- Extra 550mm tall 4-light beacon on the roof

- Dust extraction unit

- Vacuum hose reel for manual cleaning

- Flat belt outfeed conveyor, width 250mm

- Flat belt outfeed conveyor for sorting failed products, width 200mm or 250mm

- Pallet output conveyor (details to be defined)

- Shuttle output (details to be defined)

- Tray handler with buffer conveyor for automatic tray stack loading/unloading

- Tray stack handover by AGV or manually

- Tray size up to 400x600mm

- Tray handler with manual tray stack loading/unloading

- Tray size up to 400x600mm

- MES communication (details to be defined)

DOWNLOAD PRODUCT DATASHEET

Learn more about the JOT Router 400 that makes routing / depaneling PCBs easy and flexible. Click to download the datasheet for more detailed product specifications.