Material handling

620 series

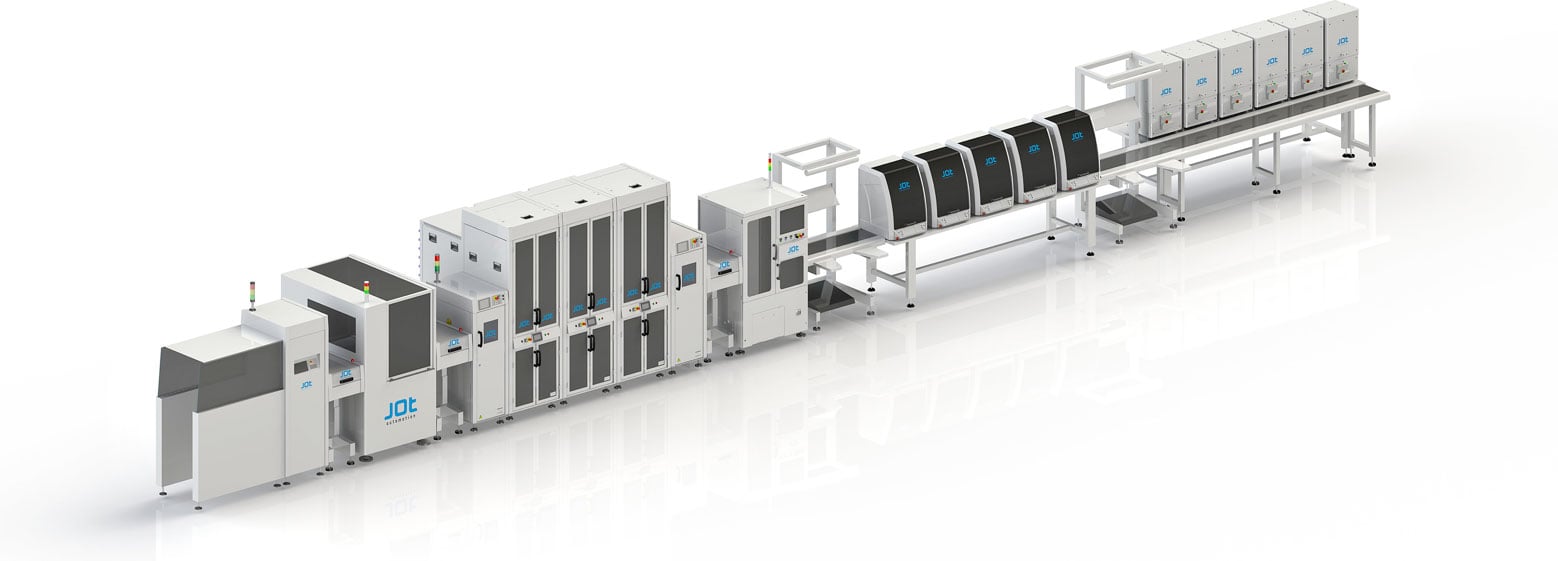

When manufacturers go big, JOT handles it. Our new 620 series board handling series is designed to meet the demanding needs of big PCB handling.

← Standard products / Material handling / 620 series

WORLD-CLASS MANUFACTURING SOLUTIONS THAT KEEP PRODUCTION LINES MOVING.

The JOT board handling portfolio covers 100% of material handling needs in fast-paced mass manufacturing. From telecommunication base stations to automotive displays to LED lighting, consumer and power electronics manufacturers are utilizing bigger PCB boards to accommodate their products’ heavier components and complex applications. That’s why they turn to JOT Automation for material handling and assembly solutions that keep manufacturing lines moving.

With decades of dependable manufacturing experience built into it, plus exceptional service, fast lead times, and the industry’s lowest total cost of ownership, the new, bigboard ready JOT 620 material handling series is fast becoming the new industry standard.

Our solutions include e.g. segmented conveyors with integrated inspection, transfer conveyors, turn units with the L, T, X function, shuttle gates, lift units, bare board unstackers, magazine buffers, FIFO buffers, line loaders and unloaders.

KEY PRODUCT FEATURES:

- Capability to offer always 100% optimized solutions based on world-class production process know-how

- 620mm width capability for big board needs

- The portfolio covers all of material handling needs

- 100% modularity enables easy configurations (line speed, width and height)

- Product lifetime +25 years

STANDARD FEATURES:

- Width series 620

- PCB Length: 100–800 mm (4–31")

- PCB Width: 50–620 mm (2–23")

- PCB Weight: max. 5kg (11lbs)

- PCB max. component upper height: 100 mm (4")

- PCB max. component lower height: 25 mm (1.0")

- Conveyor speed adjustable 6 – 12m/min (configurable double speed in infeed or outfeed)

- PCB conveyor track width adjustment by hand wheel

- Conveyor track height 950mm (+/- 25mm)

- Conveyor fixed edge in front

- SMEMA electrical interface

- CE-safety compliant

- ESD-safe design

OPTIONAL FEATURES:

- Transport direction right to left

- Other than SMEMA interface if requested

- Motorized or line width adjustment

Segmented Conveyor

Download Segmented conveyor product datasheet

- Transports and buffers PCBs between process machines

- Easy mechanical connection to other equipment

- Safe, clean design with no visible motors or wiring

- Multiple-drive technology

Shuttle Gate

Download Shuttle Gate product datasheet

- Allows personnel traffic through long production lines

- Functions as a conveyor

- Fully automatic hands-free operation

- Can be used to compensate changes in line length

In-Line Workstation

Download In-Line Workstation product datasheet

- Versatile adjustments

- Large range of optional accessories

- Buffer-work-buffer configuration

- Fully integrated with conveyor track

Board Inverter

Download Board Inverter product datasheet

- Turns PCBs for top and bottom side processing

- Handles boards with tall components

- Motorized turn movement

FIFO Buffer

Download FIFO Buffer product datasheet

- Increases production line throughput by balancing material flow

- Flexibility between automatic and manual work phases

- Selectable FIFO and LIFO operation

- Cycle time less than 10 seconds

- Small footprint

- Configurable cooling time