Odd-Shape Assembly Cell

Fast component placement, high productivity

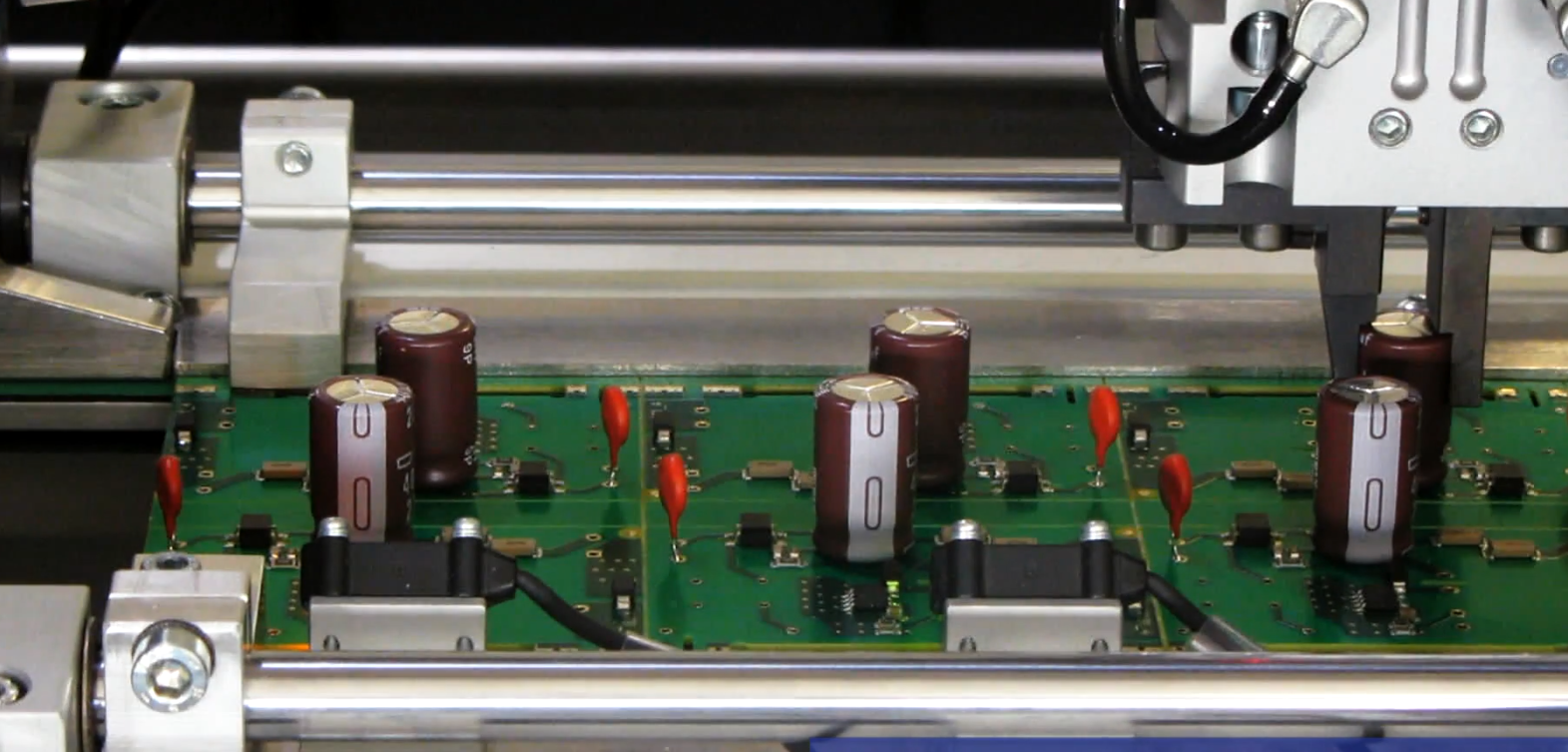

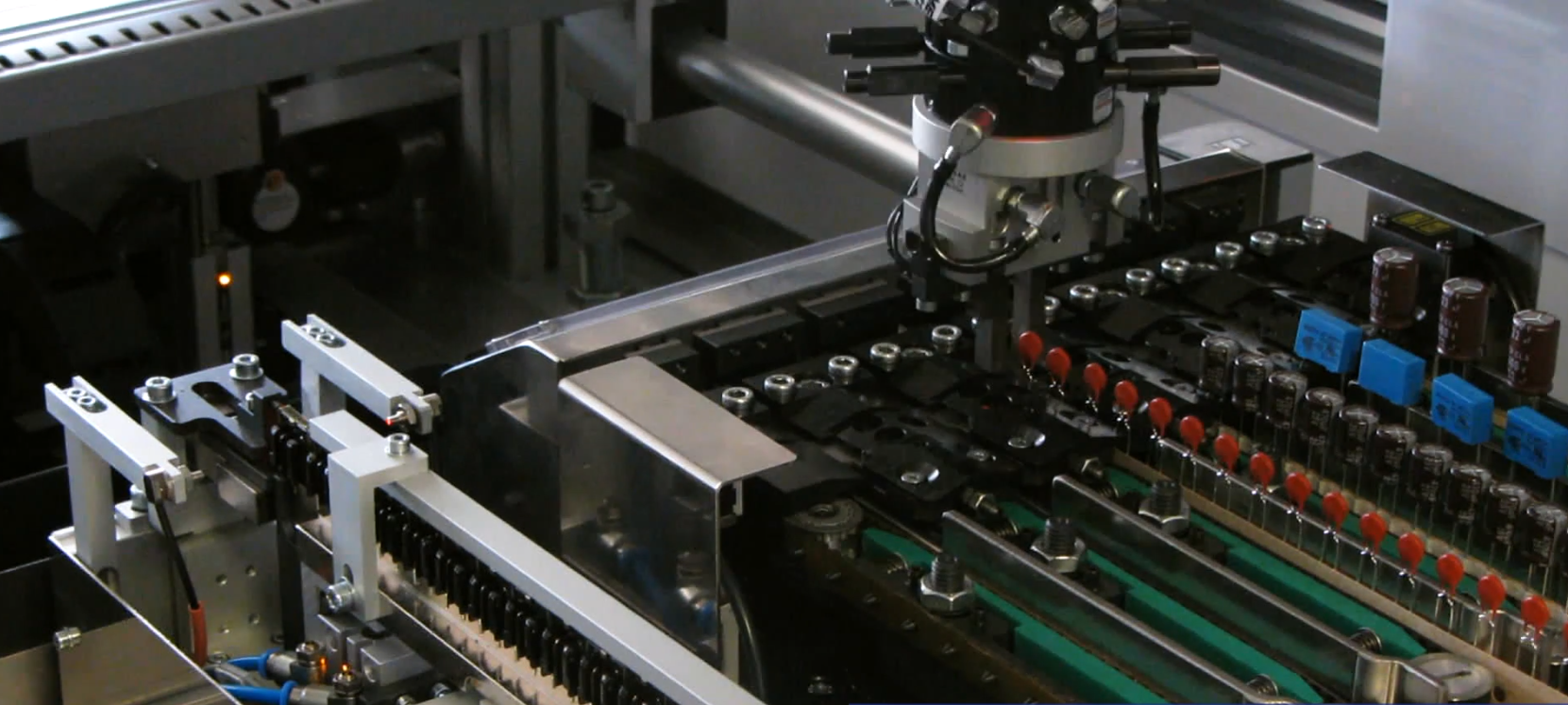

Over a hundred different kinds of component types have been assembled with the JOT Odd Shape Assembly Cell, and the number is growing. The solution has a minimized footprint of 2 m², yet feeds up to 7 different components in parallel to provide high productivity while maintaining superior accuracy and reliability in demanding production conditions.

The reusability of the platform and feeders is close to 80%, allowing the platform to grow and adapt to future business and production needs.

KEY PRODUCT FEATURES:

- Well-equipped to handle all components regardless the shape

- +100 different component types already assembled

- Cost efficient solution for odd-form component assembly

- Best-in-class on accuracy and reliability in demanding production conditions

- Product lifetime +25 years

- Close to 80% reusability of platform and feeders

- Minimized footprint 2 m² and yet feeding parallel up to 7 different components

- Easily expandable to automate +20 different processes

STANDARD FEATURES:

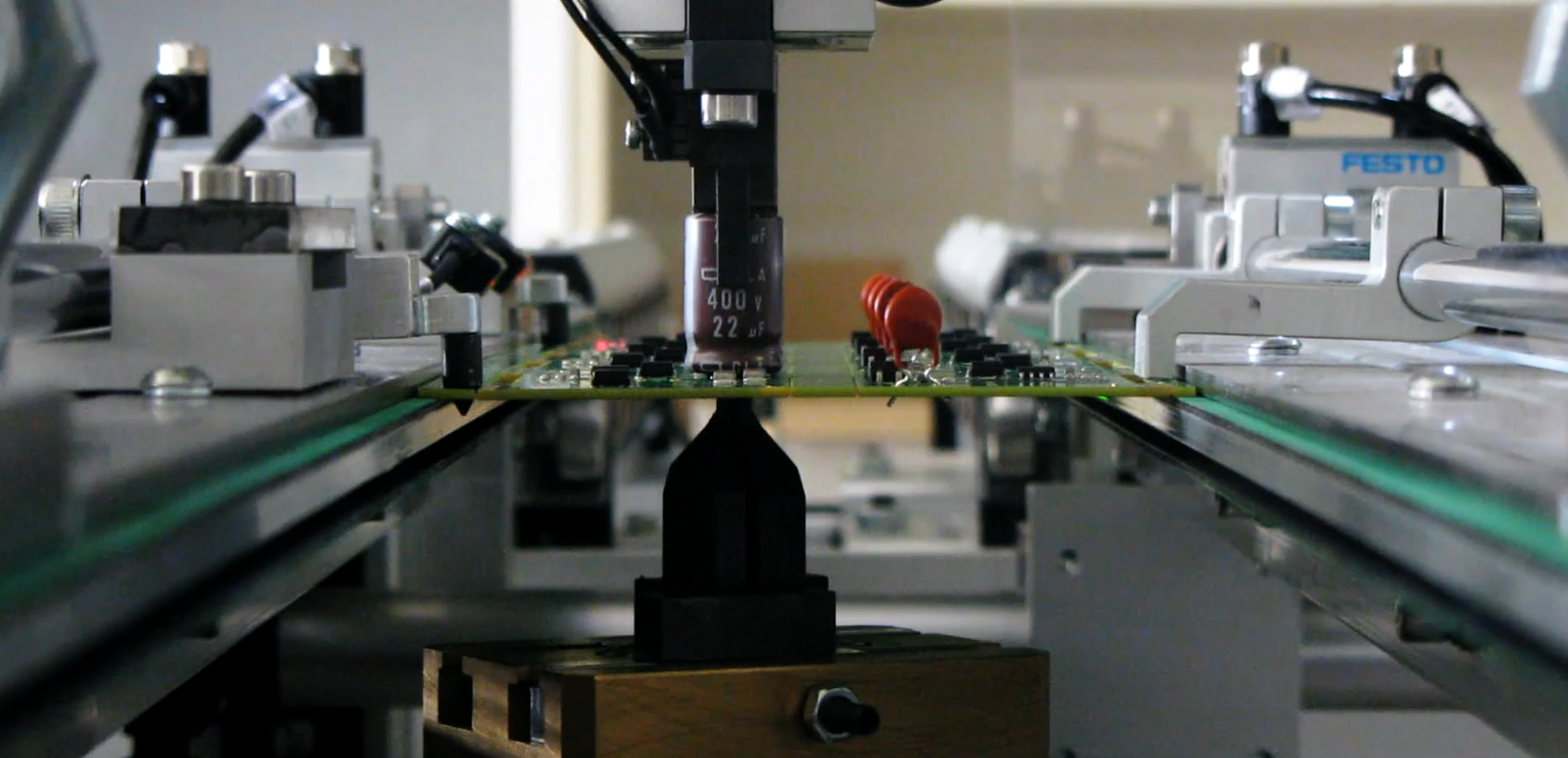

- High precision mechanical tools

- Gripper presence detection

- Component presence sensing

- Insertion tests

- Easily configurable to versatile applications

- Applicable with different types of component feeders and grippers

- Automatic tool exchange system

- Easy set up with graphical user interface

OPTIONAL FEATURES:

- Transport direction from right to left

- PCB conveyor or Pallet conveyor

- Active clinching system

- Machine vision for fiducial check

- Machine vision for component lead check

- Vision-guided component placement

- Bar code, QR or 2D reader

- MES setup

- Component feeders and grippers

DOWNLOAD PRODUCT DATASHEET

Learn more about the JOT Odd-Shape Assembly Cell that makes odd-form component assembly easy and flexible. Click to download the datasheet for more detailed product specifications.